For over 25 years.

Precision and perfection.

Since itp was founded in 1994, with just 4 employees, we have stuck to this motto and are therefore still a reliable manufacturer of precision probe elements, accessories and clamping systems for industrial metrology. With our designs and constructions, which are produced in-house according to the strictest quality criteria, we have quickly risen to become the supplier of internationally technologically leading measuring machine manufacturers and users. Thousands of customers from all sectors of industry worldwide place their trust in itp and place high demands on their suppliers in terms of quality, cost transparency and readiness to deliver.

Everything from a single source.

From the idea to the finished product.

No matter what size, what material, what configuration you need: itp has an extensive range of probe elements and accessories for all manufacturers of coordinate and gear measuring machines.

We manufacture all probe elements, accessories and configurations in complete production based on our own designs directly in-house. By using the latest manufacturing technologies, we set the highest standards for our product lines ourselves. We produce every single part with the highest possible vertical range of manufacture and all production steps are subject to the strictest quality controls. Since we do not have to go via external contract manufacturers, we can guarantee that only the best quality leaves our high-tech forge.

The best connection.

Soldering or gluing?

Soldering allows the same or different materials to be joined firmly, tightly and conductively. It is a substance-to-substance joining and coating of materials.

In bonding, the durability of the bonded joint depends on the adhesive force of the adhesive on the joining surfaces and the cohesive force inside the adhesive layer. The bonding surfaces of the two components must be as large as possible.

You decide.

Spigot or calotte?

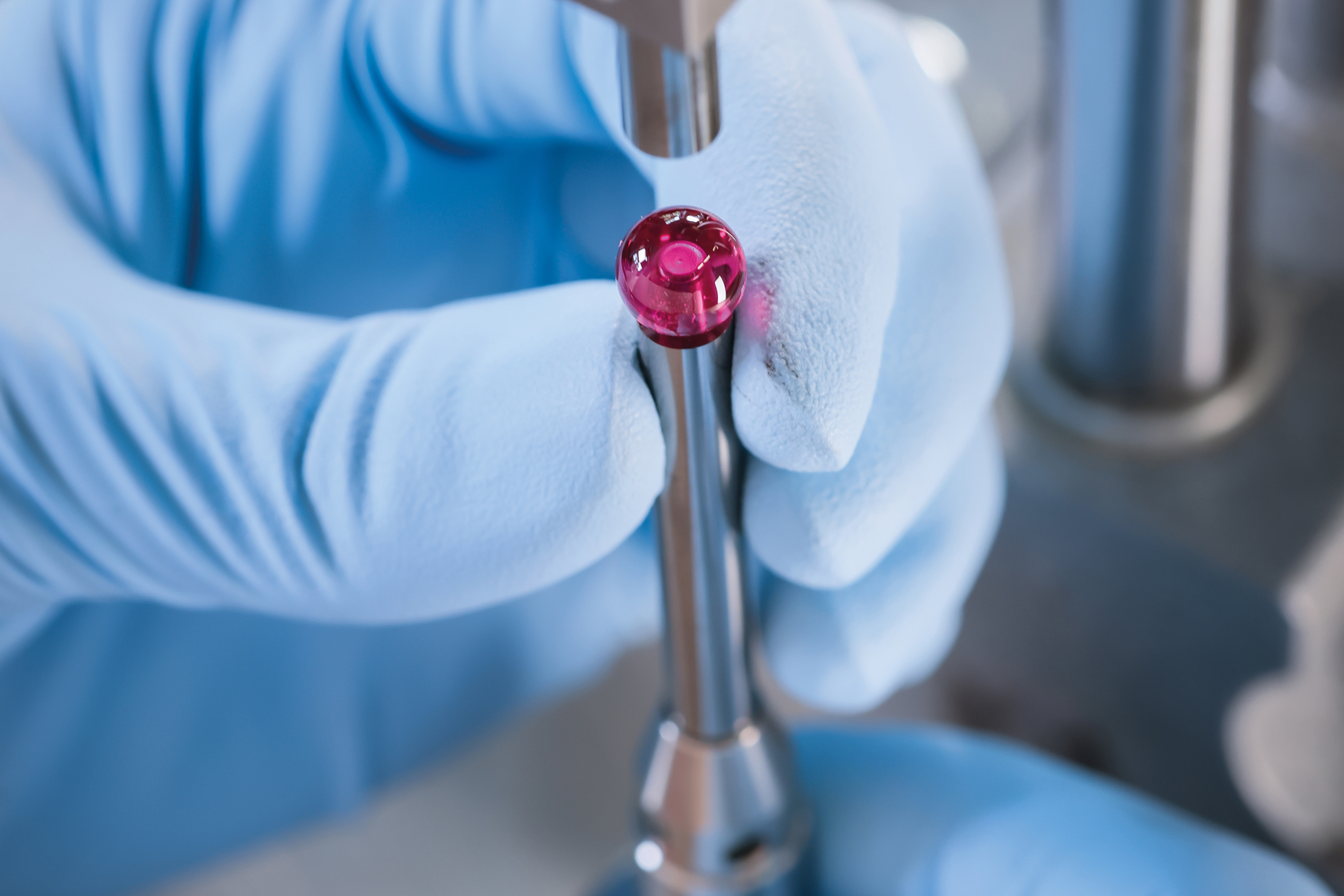

One can choose between two ways of mounting sensing balls on the stem: on the trunnion and in the calotte.

In the trunnion connection, a drilled ball is glued or soldered to a cylindrical, stepped shaft.

In the case of the calotte connection, a full ball is connected in a spherical calotte of an equally cylindrical shaft.

Best service.

That's what itp stands for.

At itp, you not only get the best quality at the best prices, but our service is also unreservedly: precision.perfection.

We know how much time pressure you are under. To make ordering easier for you, we have set up a service hotline for you at 06898/85091-0 with technical advice.

Guaranteed fast delivery

We deliver all standard products in stock within Germany using the Next-Day-Service, which means that your order will be dispatched on the same day. What you order today will be available tomorrow. Even custom-made products, which we manufacture specifically to your specifications, are usually delivered within a few working days.